Bend Test

BS EN ISO 6892-1 – Tensile testing of metallic materials Method of test at ambient temperature

Purpose of test

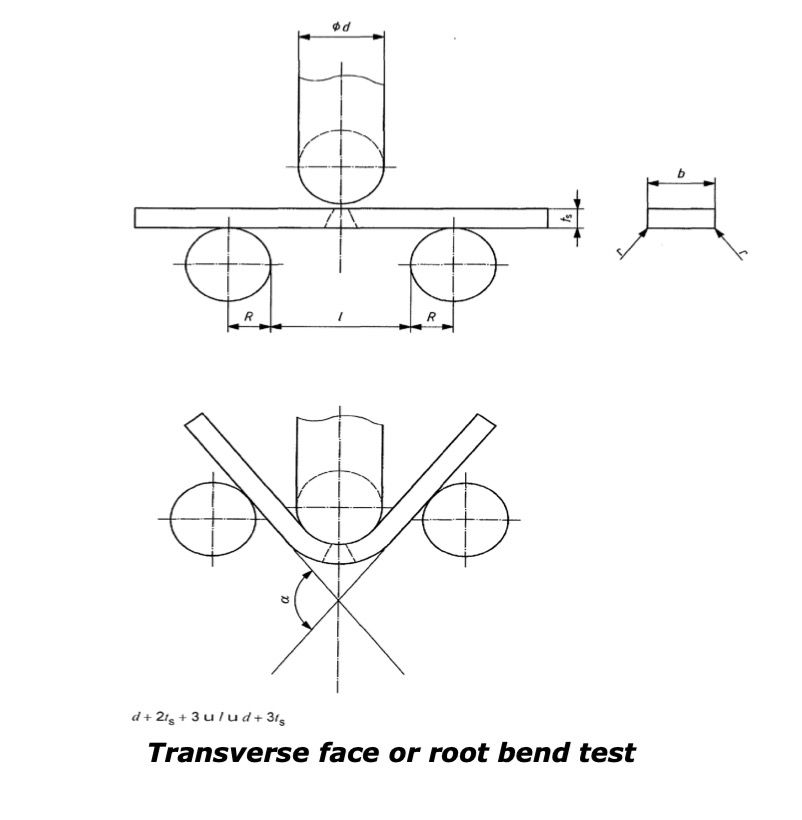

Bend tests are carried out on butt welds to determine the soundness of the weld zone. The commonly applied bend test is the transverse bend test where the specimen is cut so that the weld is transverse to the specimen length. There are three ways to perform this type of bend test on a single sided weld:

- The root bend test puts the root in tension. Main aim is to open up and enlarge surface breaking discontinuities.

- The face bend test puts the face in tension. Main aim is to open up and enlarge surface breaking discontinuities.

- The side bend test puts the side of the weld in tension. Main aim is to open up and enlarge sub-surface discontinuities.

A longitudinal bend test has the weld longitudinal to the specimen length. The inner or the outer reinforcement may be placed in tension depending on specification requirements. Bend tests may also be used to give an assessment of the weld zone’s ductility.

Test specimens

Bend test specimens are cut from designated areas of the welded assembly. The length and width, method of cutting (thermal or machine), and requirements for either removing or leaving of the weld reinforcement would be stated in the appropriate specification.

For all types of bend test, the specimen width is usually at least 1.5x the thickness and the weld reinforcement is usually dressed flush on both sides. The edges of the specimen are rounded off – normally to a maximum 10% radius.

Equipment and test procedure

Bend testing may be carried out by two methods:

- By using a hydraulically operated former to bend each test specimen through the centre of a pair of supports. The test specimen is placed on the supports, the centre point of the former brought into contact with the centre of the weld. Pressure is then applied to bend the specimen usually through to 90°, 120°, 135° and 180° as specified.

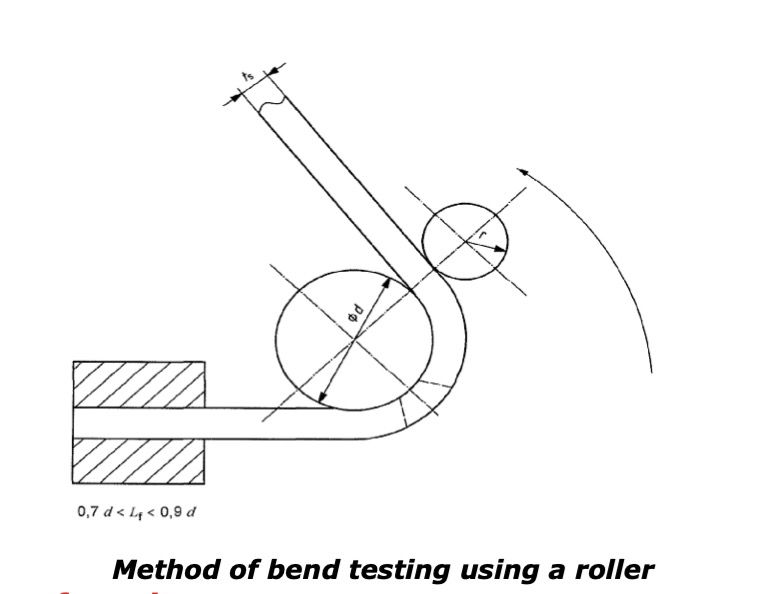

- By using a roller to bend each test specimen around a mandrel. One end of the test specimen is firmly clamped, then a roller pushes the specimen around the mandrel in an arc to the angle specified. The diameter of the former, or diameter of the mandrel, is typically four times the specimen thickness.

Evaluation of results

On completion of bending, any defects on the tension surface of the test specimen are investigated. Slight tearing at the edges of the test specimen may not be cause for rejection. What constitutes a test failure, and the action to take when a specimen fails, depends on specification requirements.